Functional testing of PCBs in use

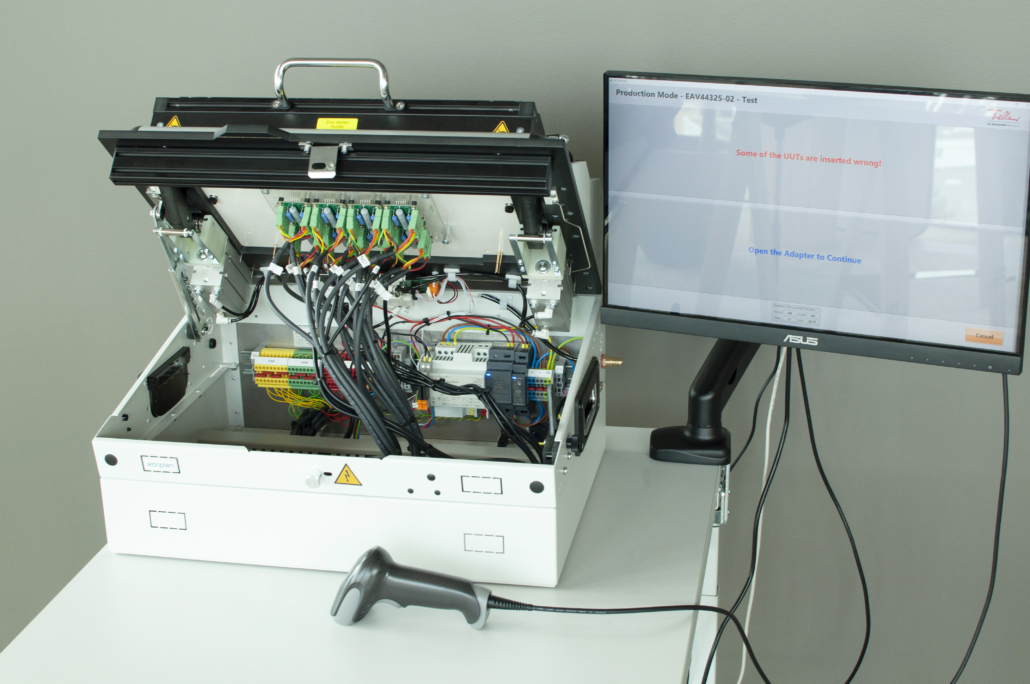

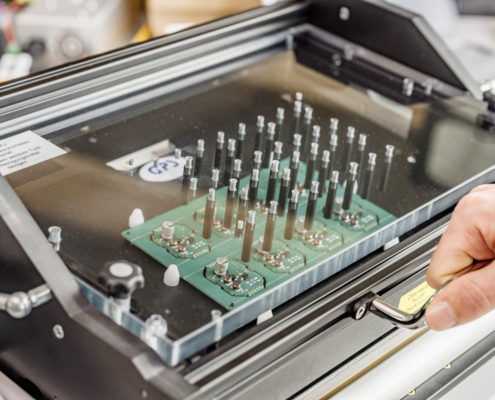

Feller AG in Horgen is the leading manufacturer of electrical and building automation components for the Swiss market. Some of the product lines are based on a modular system. For example, to build a device for the KNX bus, a standardized circuit board for the interface is available. Production of this interface circuit board is handled by an EMS partner. For continuous quality assurance, Feller decided to equip the supplier with a new testing device to perform functional tests and tasked konplan with the development and construction of this device.

Comprehensive Collaboration

Feller AG commissioned konplan to manage the complete project and provided the product specifications with the functional requirements of the new testing device. This information enabled konplan to define the requirements for the measurement technology, design the electromechanical contacting of the test objects in proven cooperation with GPS Switzerland, and deliver a detailed concept for the entire testing device to Feller. This was followed by final decisions on operational parameters and data storage. The testing device was then built according to the approved concept and the corresponding software was implemented. Finally, konplan designed and successfully performed the factory acceptance tests covering all customer specifications and including the full set of quality documentation.

Supplier quality assurance

In this project, konplan was fully trusted by the customer to develop a testing device that is used by one of its suppliers for quality assurance. This customer-specific device can test two different product types and has two separate operating modes. konplan delivered the tailor-made testing device to Feller along with the full set of technical documentation and all design rights.