Test system for sensors of a transcutaneous monitoring system

Radiometer provides powerful acute care diagnostic solutions in cooperation with health care professionals and hospitals worldwide. Transcutaneous monitoring (TCM) is a non-invasive method for patients who need continuous monitoring of oxygen (O2) and carbon dioxide (CO2) levels with minimal blood draws. Radiometer produces a wide range of sensors which measure parameters such as tcpO2, tcpCO2, SpO2 and pulse rate. During production, the functionality and tolerances of these sensors must be monitored and tested to ensure high quality. Radiometer Basel AG engaged konplan for the test system development including the full set of required documentation.

Test system scope and challenges

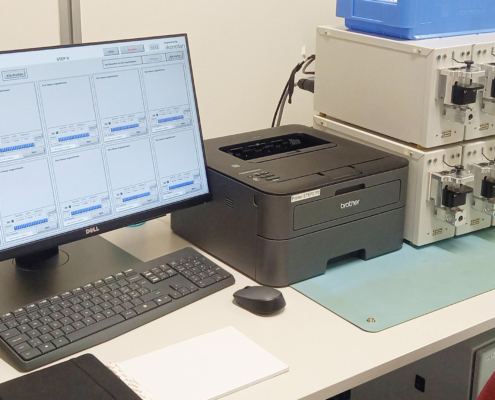

The STEP II test system was developed by konplan in close collaboration with Radiometer. The system architecture and system requirements were jointly defined using iterative methods. Combining the experience of both parties resulted in the development of a reliable system design which incorporates the best practices of current technology. A major goal of the project was the simultaneous measurement of up to 10 sensors. Therefore, the final test system consists of 10 individual test channels. The centralized control software has an intuitive PC user interface connected to a database. It supports multiple languages, autonomous backup, and integrity checks to ensure a safe and reliable system. The database ensures traceability in production and is used to generate the test report for each sensor. It was a challenge to achieve measurement accuracies of +/-0.4mV and +/-0.2µA in an industrial environment, but we were able to accomplish this.

Test system in daily use

The completed test system was successfully commissioned and proven to meet the specified requirements through factory and site acceptance tests (FAT, SAT). It is an integral part of the sensor production quality assurance program at Radiometer Basel AG and has already been duplicated several times at other production sites.