Development of the device cooling for a robotic visualization system

Our medical technology customer is a leading provider of visualization systems that are moved in the operating room on a tripod-like robotic arm. The base component of a new system with six motorized axes contains numerous electronic components that generate a considerable amount of waste heat. In this project, konplan was asked to design the system in such a way that the sensitive electronics could never overheat. In addition, the noise level of the fans should be minimized to provide an operating room environment that allows the surgeon to remain fully concentrated.

Optimal system design through calculation, simulation, and construction

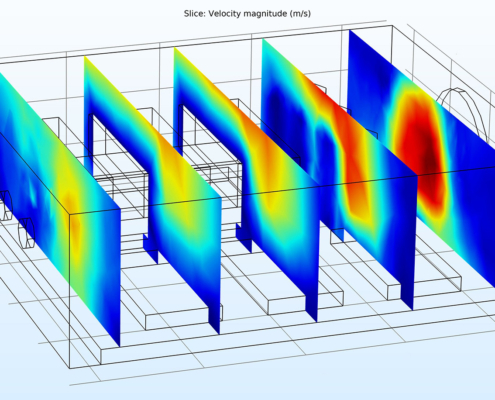

konplan quickly put together an interdisciplinary project team with engineers from different areas of expertise. First, using a Modelica model, the basic thermal design of the system was created (e.g., air quantity calculations, electronic component layout, determination of the necessary pressure build-up). The heat capacities and transfer coefficients were also considered. Afterwards, the calculated operating parameters could be measured and verified in a climate chamber. In addition to CAD system detailing, CFD simulations were performed to better understand the air mixing properties and to reduce pressure losses.

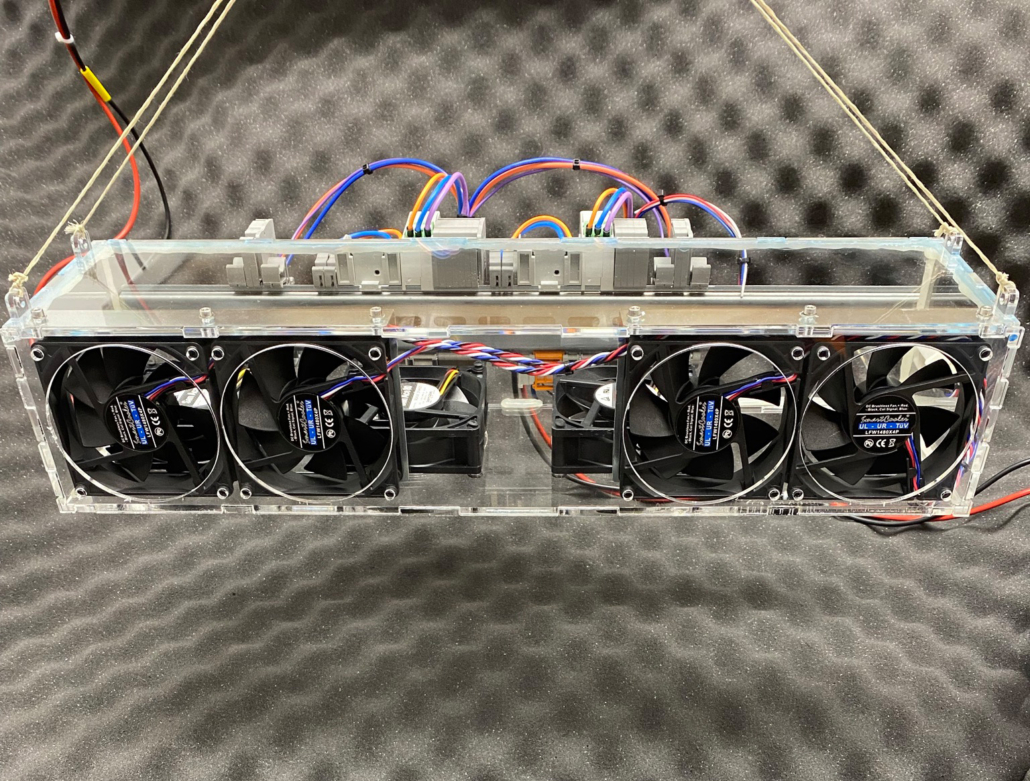

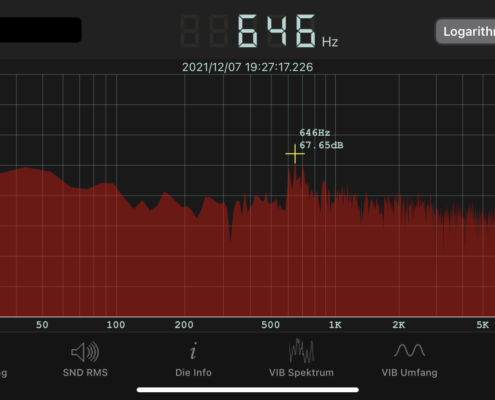

Acoustic optimization through prototype construction and measurement

Pressure losses were not only used to select the ideal fans and operating parameters, but also allowed acoustic optimization to silence disturbing frequencies. In this phase, the customer greatly benefited from the infrastructure at konplan including workshop, laboratory, and measurement technology. This allowed testing of the optimizations quickly and iteratively while minimizing the effort required from the customer. After konplan implemented the results in CAD, a tested and substantially optimized system was turned over to the customer prior to the start of production.