Dry laundry – fast and energy-efficient

With Swiss perfection, V-ZUG develops and produces appliances for the kitchen and for gentle textile care. Thanks to new technologies, these modern and reliable products make life at home easier. High-quality textile care is a tradition in Zug. The devices are characterized by their resource-saving and quiet functionality as well as their minimalist design with intuitive operation. Our know-how and commitment went into the development of the new generation of tumble dryers to create a sustainable, high-performance, and aesthetically pleasing product.

Customer-oriented collaboration

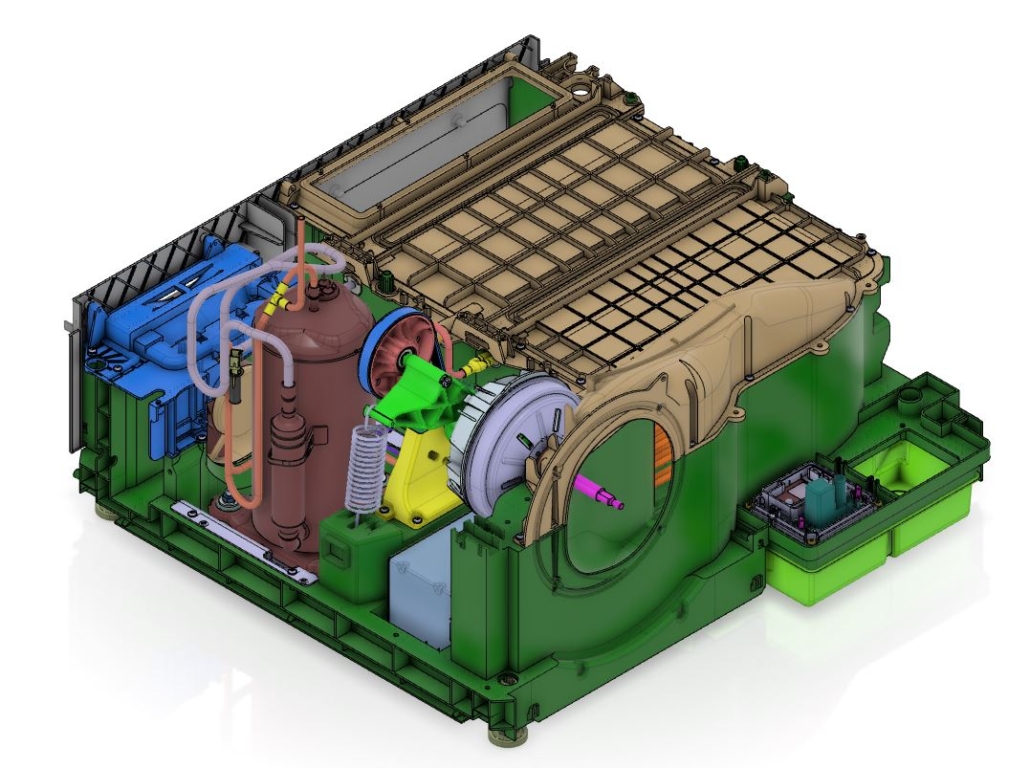

Starting with the development of a functional model, our employee was integrated into the project team at V-ZUG. The responsibility included the plastic-friendly design of injection molded components that form the base of the dryer. Close collaboration with the local employees at V-ZUG enabled a quick response to changes in the requirements. During the building of the functional models using prototype parts, our employee supported the process with a hands-on mentality. In consultation with internal and external partners, the function of the module assembly was continuously improved. Using plastics-specific know-how, the components were designed for production using the injection molding process. konplan contributed to product development in several of the project phases.

More comfort with lower energy consumption

By proactively recording the needs of various stakeholders, the assembly is simplified, and the serviceability of the devices is improved. The use of new components and technologies as well as the flow-optimized design of the plastic components reduces the energy requirements. This satisfies the stricter EU energy regulations and concurrently fulfills the vision of V-ZUG for outstanding household appliances.