A feasibility study is particularly useful when risks cannot be assessed, the feasibility of the product is questioned, or the existing fundamentals simply are not sufficient to define the final product requirements. Occasionally, it is also good practice to compare several product versions or implementation variants before making a final decision.

We perform technical feasibility studies in the fields of electronics, mechanics, software, and process technology. This enables you to mitigate risks at an early stage and gather valuable information for the product development. In addition, you can also determine the economic feasibility and legal aspects (e.g., applicable standards, classification as a medical product, etc.).

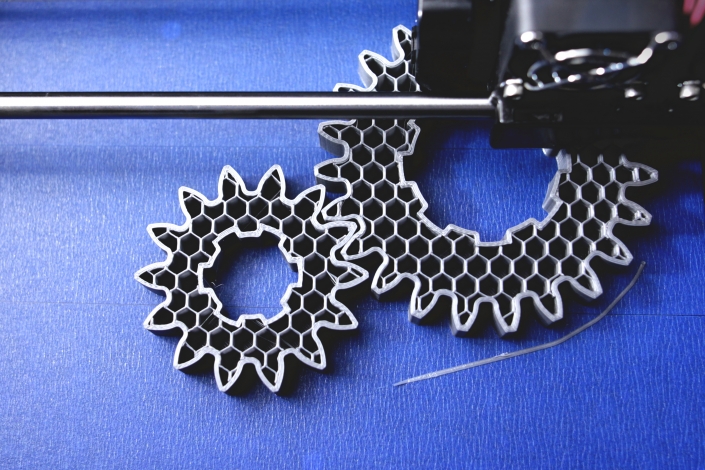

Normally, the feasibility test includes the development and construction of functional models, i.e., initial prototypes that test the individual functions of the product. See rapid prototyping

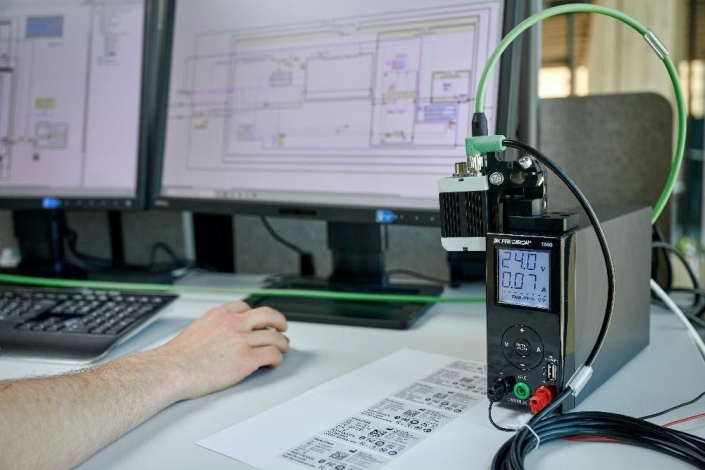

In some cases, additional equipment may be required to develop functional models which automate, test, or measure something (e.g., measurement technology for developing new types of sensors). See Test Equipment and Test Automation

In addition to technical testing, feasibility studies can also perform numerous other analyses such as expert surveys, stakeholder requirements, patent clarification, etc. We are happy to support you holistically.