KITRO’s vision for industrialization

KITRO, a leader in automated food waste management solutions, sought to industrialize the electronics of their measurement equipment called TARE. KITRO has developed the hardware for the camera system in a first iteration but needed support to reach mass production readiness and CE compliance. Their vision was to streamline the hardware design, increase reliability and ensure compliance with industry standards. Furthermore, additional topics were covered related to automating the fleet management to ease production of higher quantities and integrating all new hardware features into the embedded firmware.

Flexible hardware and software dev support

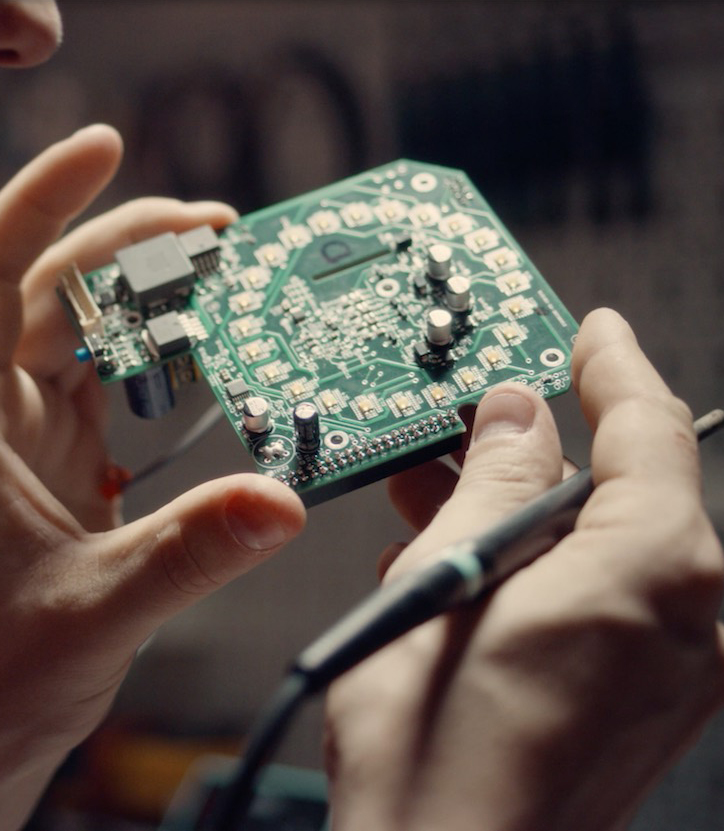

konplan started with a design assessment and collaborated closely with KITRO to finalize the hardware design of their camera system. Our approach included a deep review of the existing design, consulting in EMC compliance and modifications to the schematics and layout.

Additionally, we supported KITRO on both the embedded and cloud software in order to improve fleet maintainability. Our structured process and experienced team provided KITRO with the necessary expertise to achieve their goals.

Enhanced Efficiency and Compliance

The project resulted in a finalized hardware design ready for mass production and improved software infrastructure for device provisioning. KITRO benefited from konplan’s experience in reliable PCB design, reduced development time and flexible engineering support.