Development of an automatic calibration solution

Our customer is an international company for the development and production of diagnostic products. They characterize and validate these products in their own research and development laboratory using self-developed and highly sensitive measurement technology.

Previously, these measuring devices were manually calibrated and adjusted. Each device can include as many as 20 channels for measuring voltage and current in the microvolt and nanoampere ranges. Also, there are 100 instances of this equipment to be managed. Therefore, manual calibration and adjustment is very time-consuming and prone to human error.

Holistic product development

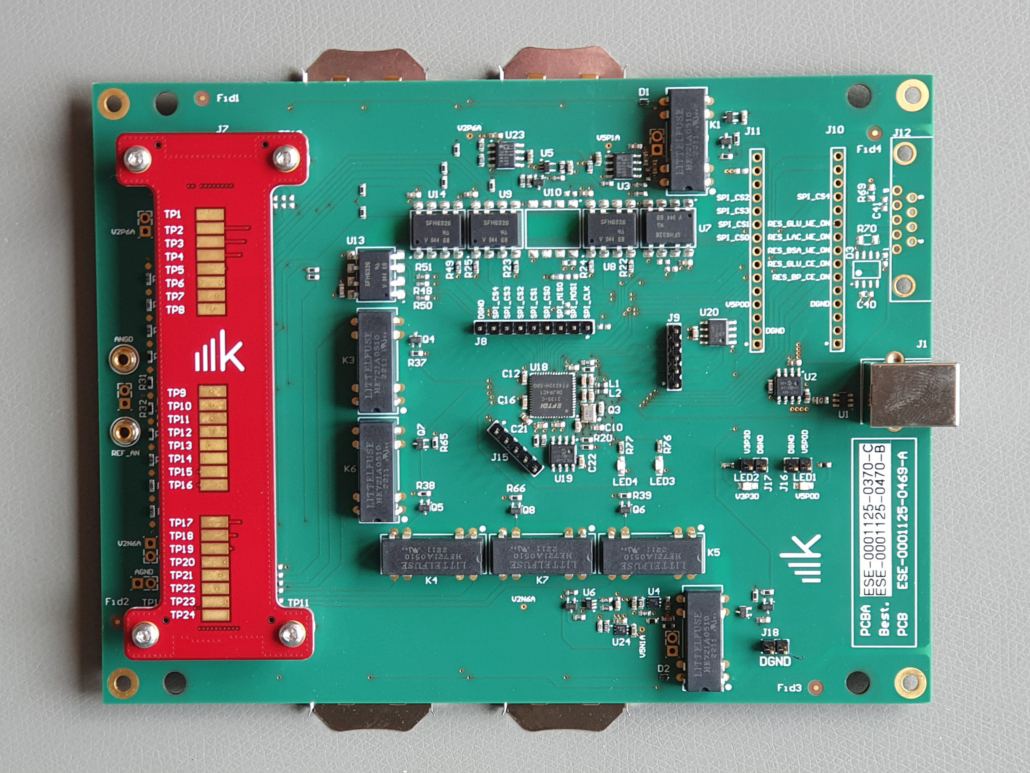

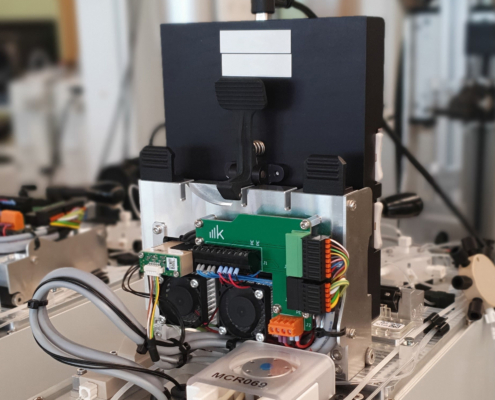

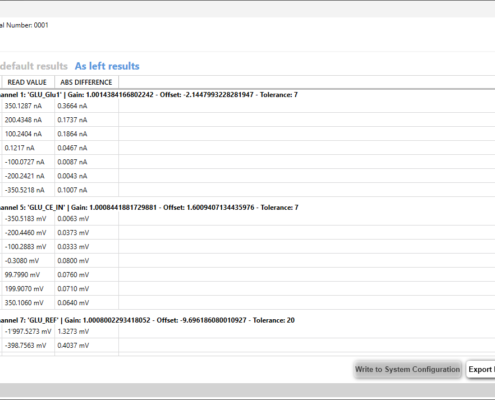

Working together with the customer, a new laboratory device was defined and developed that enables automatic, PC-supported calibration and adjustment. The challenges were minimizing the contact time at the measuring points and ensuring that the calibration device design will protect the entire measuring chain during contact with the measuring equipment. Also, galvanic isolation was required between the analog circuits and the PC to prevent measurement interference. The adjustment is accomplished using a .NET-based application where 5-point measurements are performed to calculate and save the gain and offset corrections.

Reliable calibration and efficient handling

In this project, the customer benefited from konplan’s know-how in the areas of software, design, and circuit technology and received a specifically developed calibration and adjustment device. This device allows the customer to reduce calibration time from approximately one hour per measuring system to about eight minutes. The automated support also ensures more efficient handling.