Development of the EOL testing system for breast pumps

Medela is a worldwide provider of innovative, research-based products for feeding babies with breast milk, as well as medical solutions for hospitals and clinical training. At the start of its collaboration with konplan, the company was developing the “Freestyle Flex” mobile double electric breast pump and had set the goal for pilot series and bulk production in approximately one year. In close cooperation with Medela, konplan was hired to develop, manufacture, and launch the end-of-line (EOL) testing system.

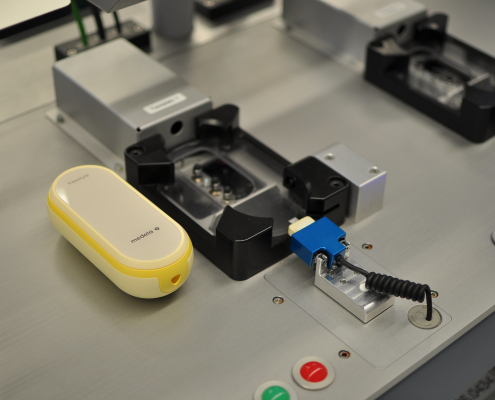

Compact and intuitive testing system

The testing system was designed to have two test stations with manual loading of items to be tested. The test items are then automatically identified using a barcode scanner and camera system followed by simultaneous testing at both stations. The parameters tested include the BLE connection, touch and LED functionality, noise production, charging capacity via USB connection, battery status, and the generated vacuum.

konplan implemented the complete testing system based on the URS of the customer from conception to product launch. The hygiene and reliability requirements were particularly challenging. The control software was implemented in LabVIEW based on the customer’s existing software architecture which was expanded to include the functionality of the new generation of pumps.

Successful testing system for over 1,000 DUT per shift

With konplan, Medela had a strong partner at their side with valuable experience in testing technology and who was able to implement the production tool according to ISO 13485. The test system is successfully integrated into the production line. The high First-Time Right Ratio (FTR) of 99.8% proves that the testing system is extremely reliable. The resulting throughput also exceeds the requirements.