Development of an end-of-line test system

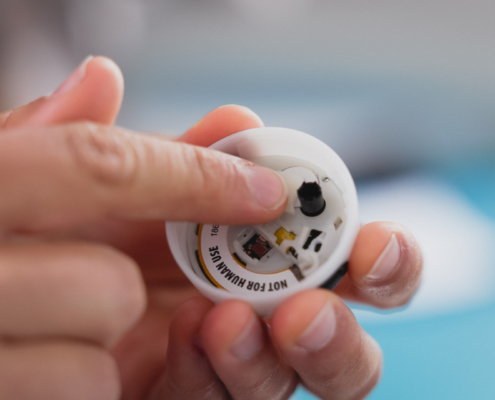

PharmaSens AG has tasked itself with improving diabetes management through innovative solutions. As a result, and with the support of konplan and others, PharmaSens developed the creative insulin patch pump “niia essential”. This compact insulin pump is attached to the abdomen or upper arm of the patient and administers personalized insulin doses at individually adjustable intervals to maintain stable blood sugar levels within the normal range. The pump consists of a reusable controller unit and a disposable component with an insulin reservoir. Production of this Class II medical device requires the highest quality standards. konplan was allowed to develop, produce, and qualify the end-of-line test system for PharmaSens.

Modular Design

The test system had to meet the technical requirements, the framework conditions of the future production site, and should also be easily expandable. Therefore, it was important for konplan to define all the requirements at the beginning of the project to create a modular system concept where each pump goes through four test stations. At the end, and only if all tests have been passed, the serial number is applied, and the device is ready for operation. In addition to the mechanical, electronic, and software development, it was also necessary to extend the firmware for proper communication with the pump.

Successful Qualification and Production

PharmaSens received a test system from konplan that ensures the flawless functioning of visual and audible indicators, buttons, Bluetooth, motors, insulin level checks, and more on every pump. The system was qualified at konplan and used for the initial production runs before final turnover to the customer and requalification at the new site.