How we produce innovative solutions together – a picturebook project

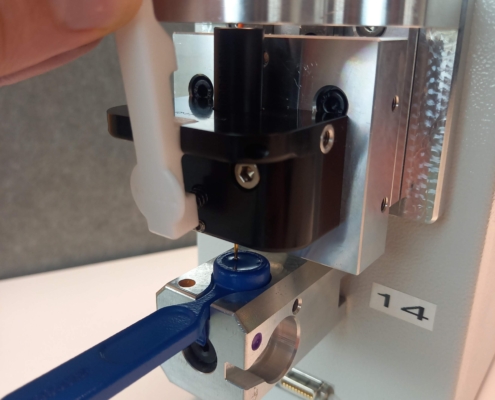

Radiometer is, among other things, active in the field of transcutaneous monitoring (TCM) and produces a wide range of medical sensors that measure parameters such as tcpO2, tcpCO2 and SpO2. During production, these sensors must be checked for functionality and tolerances using special measuring systems to ensure a flawless product.

The catalyst for this project was that an important component of the existing measuring system was being discontinued and a replacement needed to be found. This is why Radiometer turned to konplan for support. During project discussions, we realized that a revision of the measuring system could also include additional improvements, and the project scope was expanded.

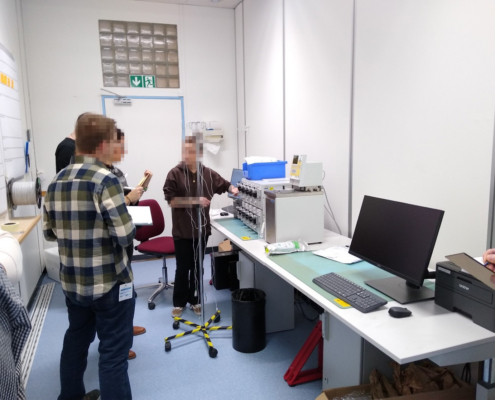

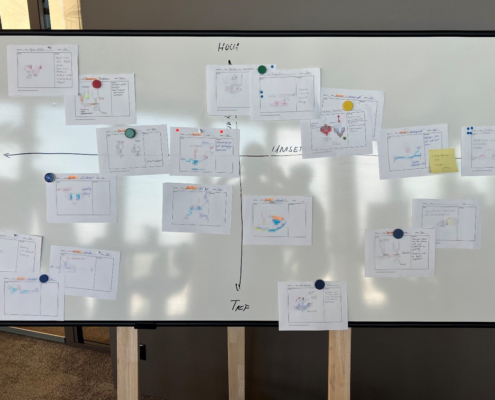

Initially, konplan began the project by organizing an on-site workshop at Radiometer to observe and record the specific work steps in production, conduct interviews with production employees, and other preparatory tasks. This helped us to define the development requirements and restrictions based on various perspectives. Then, in conjunction with the project stakeholders, the existing pain points were prioritized and the essential requirements for the new system were identified.

Based on the workshop results, konplan formulated various possible solutions in an ideation phase. Then, they were checked for risks, evaluated, accepted or rejected, developed further, and underwent basic technical tests. The best solutions were discussed with Radiometer. These solutions covered a broad spectrum, i.e., from almost identical to the existing principle to a highly integrated and automated solution. The results were presented to Radiometer including various aspects such as complexity, maintenance effort, risks, reliability, and required investment. In conclusion, two consolidated solution variants were chosen for further development.

Prototypes of the two variants were built and integrated with one of the two production systems. This allowed the variants to be tested and checked for stability in a real, production-like environment for several weeks. Eventually, the simpler variant showed greater reliability with less maintenance effort although it has the disadvantage of less automation.

With the experience gained, further minor improvements to the system were made. Finally, the new measuring system was alternately installed on the first and then the second production line to avoid downtime.

For konplan, this project was a complete success for several reasons:

- The customer is fully satisfied with the system results and performance.

- The constructive teamwork between Radiometer and konplan led to a win-win situation. Radiometer contributed its high level of expertise in TCM and sensor production while konplan contributed its extensive knowledge of innovation management and product development.

- It was a very interesting, creative, and innovative project with excellent collaboration.

- The different perspectives were able to be collected and led to an optimal solution.

- The new measuring system is more user-friendly, more reliable, and requires less maintenance.

- Only minimal changes to the existing, validated system were required and, if necessary, the new system could quickly be removed. In the end, only a small part of the system had to be revalidated.

- The project was successfully implemented within budget.

- Both technically and personally, everyone was a winner.

This project was a perfect example of friendly and motivating collaboration between konplan and its customers which led to an optimal solution.

______________________________________________________________________

Author: Ivo Locher, Program Manager

We are here for you – send us your request!

Developing together! We put your ideas into practice and accompany your projects until they are ready for the market. Get in touch with our experts now.