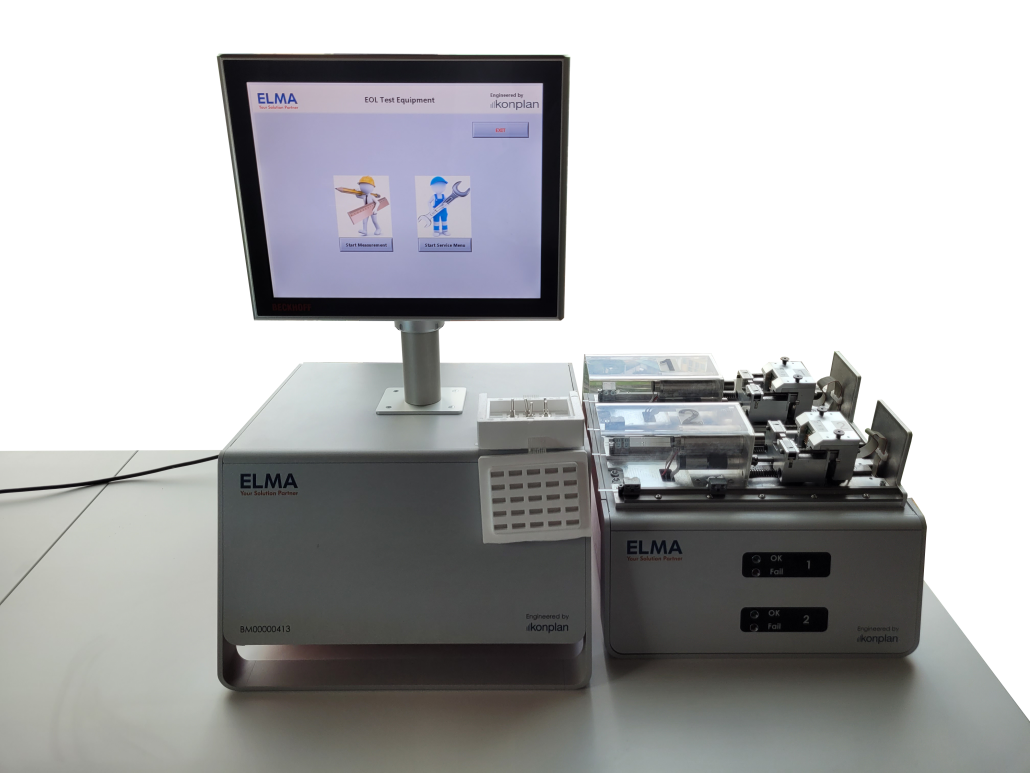

Testing system for the multi rotary switch MR50 from ELMA

ELMA is a leading global provider of embedded computing solutions. Their product range includes a variety of HMI rotary switches. These switches are characterized by an extremely high level of reliability and robustness for use in many applications including the medical and aerospace industries.

Due to growing demand, ELMA needed an efficient solution to fully test and validate large quantities of product before delivery. To achieve this goal, the development of a semi-automatic End-of-Line (EOL) testing system would be required. The system must be able to check all functional and non-functional features for approximately 50 different versions of the MR50 rotary switch.

Modular architecture for maximum flexibility

konplan worked together with ELMA to analyze the requirements and proposed a modular, cost-effective testing platform which can be expanded to accommodate the various rotary switch versions by using adapters and configuration files. The control unit contains the industrial PC and basic measurement technology as well as the position controller.

The testing station can hold two components for testing and contains the motors for automatic input, switch operation, and the version-specific measurement technology. A small electromechanical adapter allows the system to be converted in approximately 2 minutes to accommodate the different versions of the rotary switch series.

konplan designed the testing platform for independent operation of both nests which practically eliminates operational delays.

A touchscreen PC provides a user-friendly software interface based on ELMA requirements. The testing system uses the current switch testing order to request the appropriate combination of mounting unit and adapter for the switch type. The software also loads the configuration file containing the specifications for this switch type. The configuration data can also be adjusted for additional, customer-specific switch types.

Reliably aligning the connection pins of the rotary switch with the precision cup test needles was a real challenge. This required the highest level of mechatronic precision.

Enormous relief for the end-of-line quality inspection

With the development of this testing system, ELMA can fully and automatically test 100% of the MR50 products as well as other switch models in all variations (including customized designs) within 30 to 60 seconds and with reproducible results. These comprehensive, fully documented tests are a major competitive advantage in the high-end component market.